Cloud-Based Monitoring Project Introduction:

Tech Manufacturing, a long-time manufacturer of machined metal parts for aerospace clients such as Boeing, Lockheed Martin, and Bombardier, needed to raise production capacity and reduce lead times for their clients’ largest and most urgent orders. With their 5-axis CNC machines already running 24 hours a day up to 7 days a week, Jerry Halley, Chief Engineer at Tech Manufacturing, looked towards smarter operation and real-time performance data to increase the productivity and useful life of their existing machines.

“We needed a better understanding of how our machines were actually performing for us in real-time,” said Halley. “Live and historical machine performance data would also help us identify technical or process issues that were detrimental to productivity.” With a combination of hardware and software, a CNC monitoring system would collect, analyze, and visualize the necessary performance metrics. However, Halley needed to weigh the productivity gains of such a system against the cost and effort of deployment, especially if it involved a new and unfamiliar server-based IT infrastructure. The ideal system would be easily deployed without specialized IT equipment, knowledge, or effort, and would not require repeated software installation, updates, or configuration.

-Live dashboard with alerts based on historical and target performance metrics

-Easy to use with existing CNC machines that may not have built-in Ethernet interface

-Does not require investment or expertise in specialized IT infrastructure, servers, or software

-Knowledgeable and experienced integration and vendor support team

Solution:

Tech Manufacturing selected Shop Floor Automations, one of the most prominent systems integrators in North America specializing in CNC monitoring systems, to assist with cloud-based monitoring. Each CNC machine was connected to the existing local area network, so no additional IT infrastructure was required. For legacy machines that did not have a readily available Ethernet port, Shop Floor Automations provided an easy-to-deploy solution that was developed with Moxa. “The industrial networking units from Moxa make it easy for us to get our clients’ legacy machines connected to the cloud,” said Greg Mercurio, President of Shop Floor Automations.

“For industrial users like Tech Manufacturing, these solutions are invaluable in extending the capabilities and useful life of their still-functional but older CNC machines.” With the local network connected to the Internet, machine performance data was easily viewed and analyzed by cloud-based software such as Scytec DataXchange or Predator Machine Data Collection. Key performance metrics were organized on a visual dashboard so owners and machine operators were able to see exactly how productive each cell was, down to the machine level. Read more below.

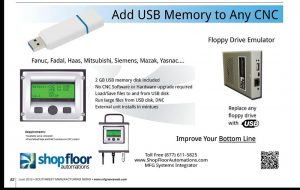

Replace your floppy disk drives and media with USB solutions.

Replace your floppy disk drives and media with USB solutions.