2017 Manufacturing Technology Trends

Being a technology-related company, part of what we do is about keeping up with trends. We were definitely excited to see we meet the criteria of this beautifully articulated piece from the ARC Advisory Group on 2017 Manufacturing Technology Trends to watch for.

“The automation industry appears to be evolving at a faster rate right now than at any time in its history,” writes Craig Resnick of ARC, which is a research and consulting group that keeps up with industry changes, especially in terms of IIoT technology. “Commercial technologies continue to infiltrate the industrial automation space, especially wireless and mobility solutions.”

“One of the biggest end-user challenges remains unscheduled downtime,” Craig says. ” IIoT-enabled solutions, such as remote monitoring and predictive maintenance, can help minimize, if not totally eliminate this, which would deliver a rapid ROI (return on investment).”

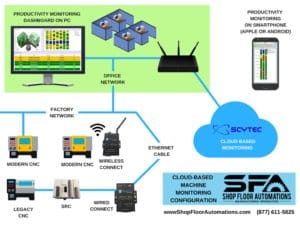

With machine monitoring solutions such as Predator MDC and Scytec’s DataXchange, as well predictive maintenance solution Bigfoot CMMS, we combat the issue of downtime and meet the needs that Craig mentions. It is also worth noting that DataXchange can be integrated with Bigfoot. As far as wireless and mobility solutions, we offer many hardware options, as well as many of our software options being able to be accessed via Smartphones and tablets, where you can receive notifications of any machine issues.

“The Industrial Internet of Things…offers tremendous potential to transform and improve business processes,” Craig continues. “But prospective end users need help to quantify and justify the associated investment, and – in some cases – the associated risk.”

If you need any help with convincing the decision maker of your shop floor to consider these solutions, or if you have doubts before you make these investments, give us a call today! We are toll-free at (877) 611-5825 and we also have a responsive chat feature on our website. We can also be contacted via social media.

This is an archive of our January 2017 topical newsletter:

This is an archive of our January 2017 topical newsletter:

What is DNC Software?

What is DNC Software?