Predator MDC

MDC Key Features

- Real-time, automatic machine data collection

- Process data via various charts & reports

- Monitor OEE, cycle time, idle time, setup, teardown, downtime, & more

- Improves manufacturing by supplying accurate shop floor productivity metrics

- Enhance operations & make better decisions

Success Story

Predator MDC from Shop Floor Automations helped R&D Manco with productivity and was mentioned in this Modern Machine Shop piece from January 2018

Features

- Automatic and manual data collection

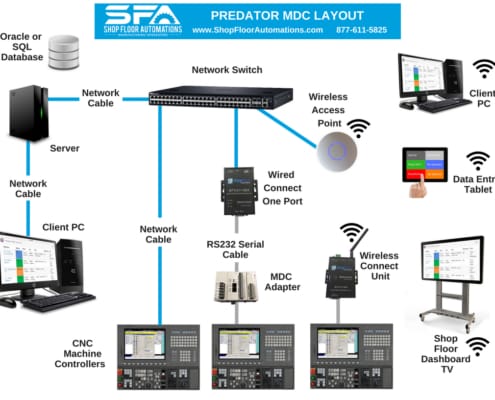

- 1 Network to monitor all your CNC machines, robots, PLCs and ATE test stands

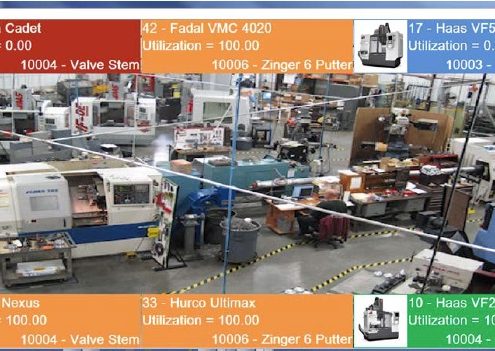

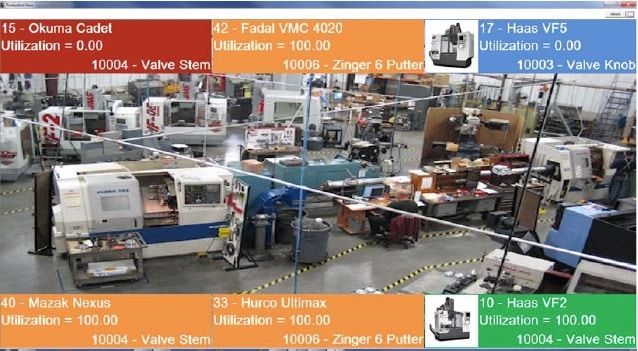

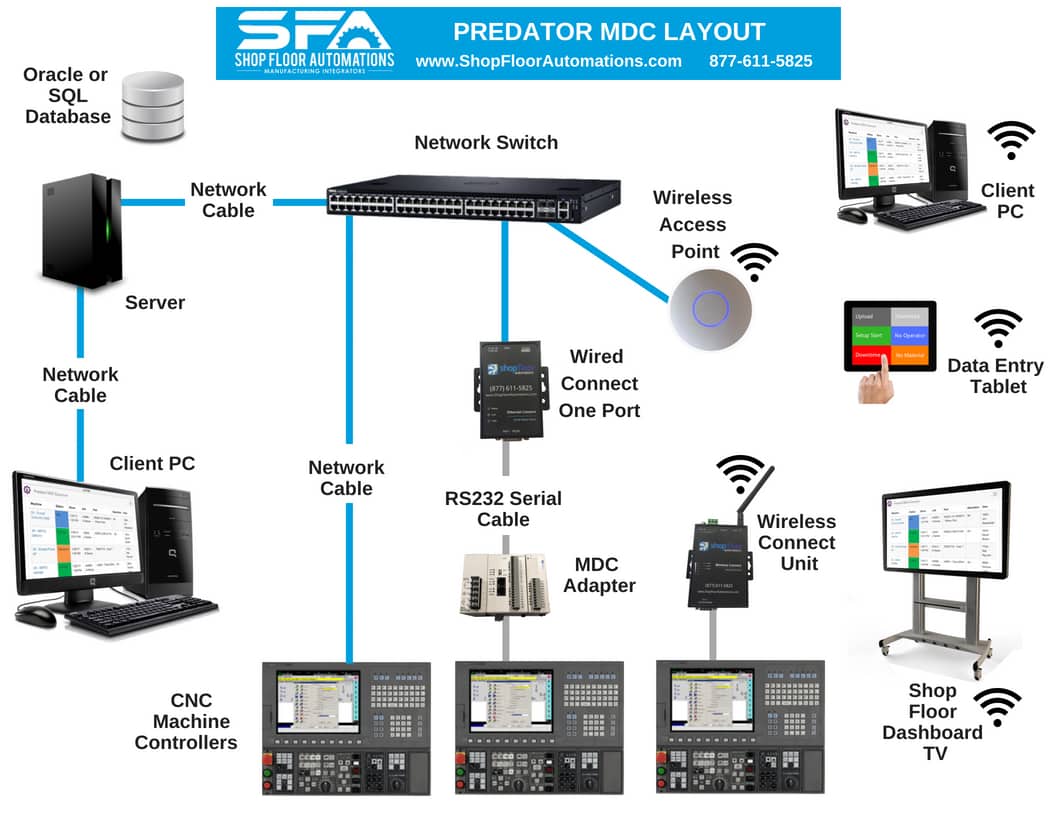

- 15 Real-time Dashboards for digital signage

- Real-time Slideshows for digital signage

- Multiple plant support

- Unlimited number of data collection events

- 30,000+ Reports and Charts

- Real-Time OEE Dashboard, OEE Charts, and OEE Reports

- Supports Wireless, Ethernet, RS232, and Parallel I/O

- Open API and database architecture

- Includes Predator CNC Service, Predator MDC Executive & Predator MDC for DOS

- Includes Predator DNC for send, receive, and drip-feed

- Use your existing ERP and MES bar coded paperwork

- Upgrade to Predator SFC

- 250+ Online help topics

- Integrates with Predator Touch HMI

Overview

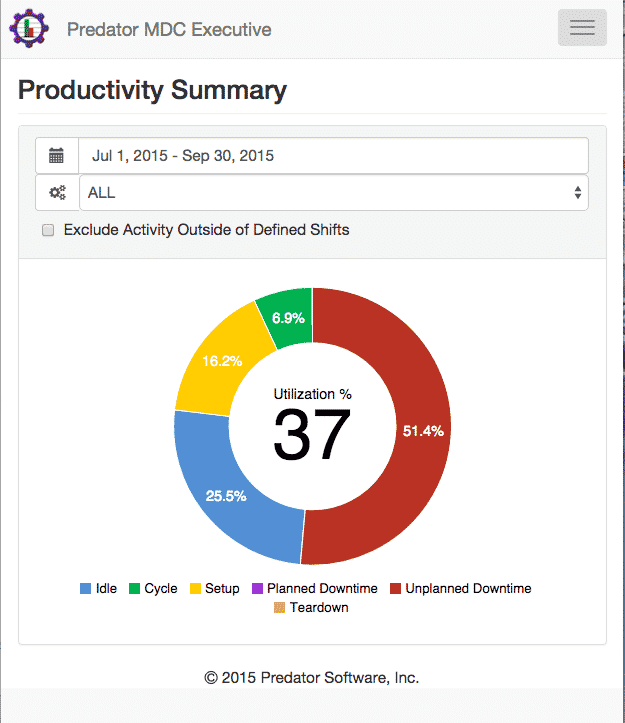

Predator MDC creates a continuously up to date knowledge base of your manufacturing performance. It quantifies how well your machines, people, and parts are produced.

With it, you can establish and compare continuous improvement results for lean manufacturing efforts. This software organizes your real-time data into actionable metrics for availability, quality, and performance. Metrics for specific machines or rolled up metrics for an entire department across multiple plants are available with a few mouse clicks.

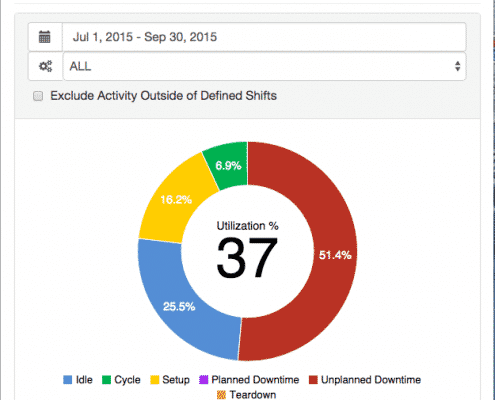

Real-time OEE Software

No more manual OEE driven data collection and spreadsheets. Real-time OEE data collection from Predator MDC with an OEE Dashboard, Performance ranking charts, Trend Analysis charts, and Reports will be a huge help on the shop floor.

Interested in Trial?

For more information from the #1 reseller of Predator Software, please call (877) 611-5825